Certainly! Laser engraving machines are versatile tools that can cut through various materials with precision and finesse. The choice of materials that a laser engraving machine can cut through depends on several factors, including the type of laser used, its power, and the specific properties of the material. Here are some common materials that laser engraving machines can cut through:

Wood: Laser engraving machines can easily cut through a wide range of wood types, including plywood, solid wood, MDF (Medium Density Fiberboard), and veneer. The laser's high energy can vaporize the wood, creating precise and intricate designs.

Acrylic: Acrylic, also known as Plexiglass or PMMA (Polymethyl Methacrylate), is a popular material for laser cutting. The laser's heat causes the acrylic to melt, resulting in smooth edges and precise cuts.

Paper and Cardboard: Laser engraving machines can intricately cut and engrave paper and cardboard, making them ideal for creating intricate designs, models, and even custom packaging.

Leather: Leather cutting and engraving with laser machines offer clean and detailed results, perfect for crafting leather products, accessories, and customized designs.

Fabric: Laser cutting is a convenient way to create intricate patterns on fabrics, such as cotton, silk, denim, and more. The laser's precision prevents fraying and ensures a polished finish.

Glass: Some laser engraving machines equipped with specific lasers can create micro-fractures on the surface of glass, resulting in elegant and detailed designs. This process is often used for glass etching.

Metal: Laser engraving machines equipped with powerful fiber or CO2 lasers can cut thin metal sheets and engrave metals like aluminum, stainless steel, and brass. These metals absorb the laser's energy and heat up, allowing for controlled melting and cutting.

Ceramics: Laser engraving machines can mark and engrave ceramics, tiles, and porcelain by removing a thin layer of the material's surface, resulting in detailed designs.

Stone: Some laser engraving machines with higher power lasers can cut and engrave soft stones like marble, slate, and soapstone. The laser's heat causes controlled fracturing on the stone's surface.

Plastics: Various plastics, including ABS (Acrylonitrile Butadiene Styrene) and polycarbonate, can be cut and engraved with laser machines. The laser's energy melts the plastic, resulting in precise cuts and designs.

It's important to note that the capabilities of a laser engraving machine can vary based on the machine's specifications. Additionally, some materials, like certain metals and reflective surfaces, might require specialized lasers or additional precautions to ensure successful cutting and engraving. Always refer to the manufacturer's guidelines and test settings before working with unfamiliar materials.

Add your answer:

Who invented the laser cutter?

The laser cutter was invented by Kumar Patel in 1967 while he was working at Bell Labs. Patel's invention revolutionized cutting and engraving processes by using a high-powered laser beam to precisely cut through materials.

What can cut through anything?

A laser cutter is a machine that can cut through a wide range of materials, including metals, wood, plastic, and more, with high precision and speed.

What do you call a beam of light so powerful that it can cut through light?

A laser. Laser beams are intense and concentrated beams of light that have the ability to cut through various materials, including other light sources.

Can you break a diamond with a laser?

No, diamonds are one of the hardest materials and require very high temperatures to break. While a laser can cut through many materials, it would not be able to easily break a diamond.

Which of the following processes uses lasers?

Inertial confinement fusion

What are laser engraving machines used for?

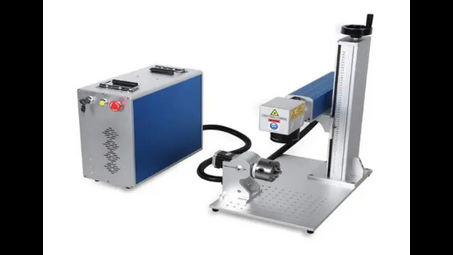

Generally, laser engraving machine has three main parts: a laser, a controller, and a surface. The laser is like a pencil - the beam emitted from it allows the controller to trace patterns onto the surface. The controller (usually a computer) controls the direction, intensity, speed of movement, and spread of the laser beam aimed at the surface. The surface is picked to match what the laser can act on.

Are laser engraving machines more expensive than a simple hammer and chisel?

"Yes, a laser engraving machine is very much more expensive than a simple hammer and chisel because of the special equipment, parts and training that go along with using a laser engraving machine."

What are two companies that offer 3D laser engraving systems"?

There are many companies that offer laser engraving systems, but two well-known companies in the field of 3D laser engraving are Trotec Laser and Epilog Laser. Both offer a range of laser engraving systems that can be used on various materials, including wood, acrylic, and metal.

What kind of items qualify for custom laser engraving?

One should only try to put a laser engraving on items such as plaques, glass, acrylic and wood. Other materials would break or melt in the process of engraving.

Why laser engraving machine is use for the engraving of rotary printing rollers and flat bed printing screens?

Tech fortune laser engraver and CNC router apply rotary jig for the round shape engraving and they can work on wine bottles, railing, and decoration materials. For the rotary engraving, the machines should be with fast speed and suitable for large quantity work. But for the different types of the glass and other materials, we need to test for some times until we get the right settings for the best result. For the wood engraving, we need to apply CNC engraving machines.

laser engraving stone?

laser engraving stone

Do you get the laser engraving on an iPod if you get it in the store?

No only through Apple Webstore.

Who invented the laser cutter?

The laser cutter was invented by Kumar Patel in 1967 while he was working at Bell Labs. Patel's invention revolutionized cutting and engraving processes by using a high-powered laser beam to precisely cut through materials.

What are two companies that offer laser engraving systems?

Two companies that offer laser engraving systems are Electrox and Shining 3D. Both companies offer different kinds of laser engraving machines and workstations. Shining 3D also offers services like 3D model design, technical training and equipment maintenance.

What materials can be cut with a laser cutting machine?

Laser cutting machines cut through a large variety of materials, but there are several laser technologies. CO2 laser can cut organic materials like wood, paper, cardboard, fabric, acrylics and plastics.

What is laser engraving?

Generally, laser engraving machine has three main parts: a laser, a controller, and a surface. The laser is like a pencil - the beam emitted from it allows the controller to trace patterns onto the surface. The controller (usually a computer) controls the direction, intensity, speed of movement, and spread of the laser beam aimed at the surface. The surface is picked to match what the laser can act on.

Used laser engraving in German?

Used laser engraving is ...hat eine Lasergravur verwendet